With the advent of the Internet and web solutions, today’s printing process has been raised to new heights. Today, customers can design postcards, photo printing, booklets, brochures directly on websites. Thanks to the web to print solution, customers can order customized products without the need for a real printer, using different types of printing techniques.

When things were automatic and easy, there was only one problem. How do you choose the right approach to product printing? Different types of printing techniques have different costs and applications.

A reliable printing provider will always help you familiarize yourself with different printing methods.

- Which Types of Printing Methods are Used by Web-to-Print Industry

- What Are The 4 Types of Printing?

- What Are The 3 Methods of Printing?

- What Model is Commonly Used in The Printing Industry?

- How Many Types of Prints Are There in Textiles?

- Which Method of Printing is Most Popular?

- What Are The Types of Printing Plates?

- Is Print CMYK or RGB?

- Which is Best for Printing RGB or CMYK?

- How is The CMYK Color Model Usually Used?

- Should I Convert RGB to CMYK For Printing?

- What is The Difference Between Web and Print?

- What is a Web-to-Print Portal?

- How do I Enable Web Printing?

- How do I Print a Web Page on Google Chrome?

- What Does Online Print Mean?

Which Types of Printing Methods are Used by Web-to-Print Industry

For the business owners who have integrated web-to-print software to their store, it is important to know about the different methods of printing that are implemented by web-to-print industry.

Following are the 8 different printing methods used in the web-to-print industry.

1. Digital Printing

In digital printing, the digital images are reproduced on physical surfaces like cloth, plastic, magnets, labels, cardboard, film etc. This kind of printing is done by industrial and desktop-sized printers. It is not necessary to keep yourself confined to a single or two colors.

Read Also: Web to Print Technology Trends 2022

Using web-to-print software, you can also create a blend of different colors to match with the design. Digital Printing asks for an image resolution of 300dpi. If the quality of the image is lower than that, it can result in mediocre printing quality.

2. Screen Printing

Screen printing utilizes different types of brightly colored inks and is often used for printing posters, t-shirts and other promotional items. Initially, screen printing was confined on silk materials. Nowadays, several different types of materials are used. During the screen printing process, a design is laid on the top of the screen.

Thereafter, it is covered with photo emulsion and exposed to light. Due to its exposure to heat, the emulsion hardens up and the rest of it is washed away by leaving one kind of a stencil whose ink can be pulled by using a squeegee.

3. Flexography printing

This kind of printing is usually operated using web presses (not related to website) which prints on long and continuous rolls of paper. It doesn’t use standard plates used in offset lithography. It makes use of water based inks and rubber plates which dry very quickly and enable faster production rates. With faster drying, more effective results can be obtained on materials like plastic.

Launch your web-to-print store with us and take your print business to the next level! Start selling personalized products with a fully-functional website in less than 48 hours.

4. Litho Printing

Quite similar to Digital Printing, Litho Printing enables the printing of full colour prints on different types of physical surfaces. It also enables one to personalize promotional products that ask for multiple printing runs. High-resolution artwork (of minimum 300dpi) is needed for this kind of printing.

5. Transfer Printing

Transfer printing is used when an image has to be applied on a curved or uneven surface. Mostly, it is used for printing on materials like porcelain and cloth like surfaces. Transfer printing asks for designs to have full digital images with vector and high resolution bitmap images which can be applied on an array of products.

6. Engraving

Engraving is considered to be the most expensive out of all the printing methods. Also, it takes a lot of time to get it implemented. When it comes to the making of royal invitation cards or business cards of high-ranking officials, engraving is the most commonly used printing method.

The image is first engraved by a hand or machine on a metal plate. Thereafter, the engraved design is filled in with ink and a paper is pressed on it. As a result, a three-dimensional kind of crisp image can be obtained. Such results are difficult to produce by using other techniques.

7. Embossing

In this process, an impression of the design is created on a surface of the product. A fixed amount of pressure is given on the objects and marks are left after the pressure is released. There are two types of embossing:

- Blind embossing: The embossed mark is of the colour of the product itself

- Foil block: After the design is embossed, it is filled with metallic paints like silver and gold

8. Embroider Printing

Through embroidery printing, artwork can be recreated by decorating the fabric with designs that are stitched in strands of thread with a needle. A special printing machine is used for bulk production.

One can provide colour references for this kind of printing. Embroiders try to match the colour hues which are nearest to the sample provided. With embroidery printing, it is better if you avoid an amalgamation of different colours.

As the web-to-print industry is widening its horizons, several ways of printing are being adopted by the online store owners. If you have an online store, it’s time you make an investment in web-to-print technology.

You can choose the type of printing that goes the best with your products and offering. Ecommerce business owners generally prefer a printing solution that is versatile and can enable the printing on different types of surfaces. Make sure you invest wisely so there are no embarrassments and regrets at a later stage.

What Are The 4 Types of Printing?

Different types of printing provide different visual effects for wallcoverings. The most widely used print processes are surface, flexographic (flexo), gravure and screen. It is important to recognize that each process is capable of yielding attractive, stylized and salable products. Each process enables the manufacturer to produce a specific characteristic look.

Common types of printing are:

1. Surface Printing

Surface printing is most often employed to reproduce a stencil-like effect for traditional florals, juvenile and country motifs. This is accomplished through the use of lightweight urethane print cylinders. The print design actually coincides with raised areas on the roller.

This raised portion is obtained by removing or cutting away to leave the desired design elevated above the rest of the cylinder (like an ink stamp). Printing is accomplished by first applying ink onto the raised areas.

The inked roller is then pressed against the material to be printed causing the ink color to be transferred from the surface of the raised design onto a moving web of wallcoverings. One roller is required for each color.

Flexographic Printing

Flexographic printing, or flexo, is similar to surface printing except the print cylinders employed are made of flexible materials, usually rubber. The Flexo process is used to yield a range of country, colonial, floral and mini-print designs. This process offers the manufacturer a technique for achieving more delicate designs than is possible with nonflexible surface rollers. Some tonal effects are possible.

Screen Printing

Screen printing is accomplished in two ways, using either flat or rotary screens. Hand screens, commonly called silk-screen printing, are carried out by using flat mesh screens held within a frame. The design image area is reproduced onto the mesh screen.

The screen or mesh area is covered with a resist, such as wax, which plugs or blocks all of the screen openings, except in the area of the design image. Ink is then applied to the flat screen. A rubber squeegee is then used to push the ink along the screen surface.

In this way ink is forced through the openings in the design area onto the wallcoverings. Ink cannot be applied in the areas previously blocked by the resist. One screen is needed for each color. This process is most often used for specialty and customized products.

Rotary Screen

Rotary screen is a high-speed production technique to replace hand screen-printing. In this system, a rotary or round screen mesh cylinder is employed. Ink is fed into the inside core of the cylinder and an internal squeegee blade is used to press or apply ink through the image area of the screen.

The ink will not flow through the rotary screen where a resist has been used to block or seal the mesh where printing is to take place. Rotary screen-printing is used for designs where a bright, solid color laydown is required.

These include graphics, contemporary and traditional floral paisley, geometrics, etc. It is also used for expanded vinyl prints. A specially formulated ink is used to print the design. It then goes through a heat tunnel, which activates a blowing agent causing the ink to expand, creating a puffed, or three-dimensional look.

Gravure Printing

Gravure printing is the one process that offers the designer the opportunity of achieving a complete, continuous color deposit ranging from 100 percent full tone down to almost a 5 percent tone. Gravure is the costliest manufacturing process since the cylinder used requires copper plating and a special photochemical engraving or etching process.

Printing is accomplished via tiny cells or ink reservoirs that are engraved into the surface of the print cylinder. In contrast to surface printing, with gravure the ink is held within tiny cells engraved into or below the cylinder surface. The deeper the cell, the darker the tone printed.

By varying the size and placement of each cell, varying amounts of ink can be deposited onto the wallcoverings by pressing the inked cylinder against the web. Pressure causes the ink to flow from within each cell onto the wallcoverings. This process is the most versatile since it can duplicate a complete range of visual effects, and is able to give an almost photographic effect.

Digital Printing

Used mostly for borders and murals, digital printing is defined as one of several non-impact technologies where the image or pattern is created, manipulated and finalized by electronic systems and printed by a computer controlled printer.

What Are The 3 Methods of Printing?

As we ponder for a new printing process, let’s take a look at the most common printing processes that has shaped the industry as we know it.

The main industrial printing processes are:

Offset Printing

Offset printing was first invented in 1875 by Robert Barclay; an Englishmen who originally used this method to print on tin. Only later, in 1904, was offset printing used to print on paper by Ira Washington Rubel.

Offset printing is where the inked image is transferred from a plate to a rubber blanket; from here it is then transferred on to the printing surface. When used in unison with lithography, the offset technique uses a flat image carrier that obtains ink and water from the rollers. The water will be attracted to the non-printed areas whilst the ink will cover the rest of the image.

Lithography

Lithography was first introduced in 1796 by a German author and actor Alois Senefelder as a method to publish theatrical works cheaply. As mentioned above, Lithography works because of the immiscibility of water and oil.

The process starts usually with an image drawn with oil, fat or wax upon a smooth lithographic limestone plate. When the stone was moistened, the etched areas would retain water; an oil based ink would then be applied which would be repelled by the water, leaving only the original drawing. To complete the process this drawing would be transferred onto a sheet of paper.

Digital Printing

With two corporations in control of the industry (Inkjet and Xerography), Digital printing was first introduced in 1991.

An Inkjet printer is the common household printer that we use in our day to day lives. If you are looking to print off a document, you would use an Inkjet printer; if you were trying to print off homework, you would be using an Inkjet printer. Because of the advancements in technology, printing is no longer a luxury item.

An inkjet printer contains multiple nozzles, each of which drop small droplets of ink that match the digital image sent to it. Inkjet printing is used for a lot of postage and signage and can be printed on paper, plastic, canvas and in some cases door or floor tiles.

Xerographic printers however, print images through the use of electrical charge. The metal drum will create a charge to attract toner particles. These toner particles are then transferred to the media that is being printed on.

These three processes are three of the most common methods of printing in the modern era; allowing us to print documents, reports, certificates and other essential media.

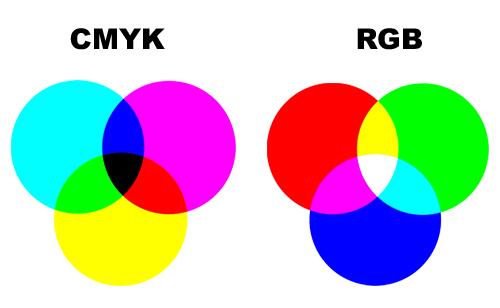

What Model is Commonly Used in The Printing Industry?

CMYK printing is the standard in the industry. The reason printing uses CMYK comes down to an explanation of the colors themselves. CMY will cover most lighter color ranges quite easily, compared to using RGB. However, CMY by itself can’t create very deep dark colors like “true black,” so black (designated “K” for “key color”) is added. This gives CMY a much wider range of colors compared to just RGB.

The use of CMYK (cyan, magenta, yellow, and black) for printing has become kind of a trope for printers. But the reason why printing uses CMYK isn’t that well known, even to many graphic designers.

On the surface, it doesn’t seem to make sense. You might even have learned in elementary school that the primary colors — red, green, and blue (RGB) — are the primary colors, from which all the other colors come.

After all, monitors, projectors, and television sets use red, green, and blue (RGB) to create all the other colors. Mixing some of these colors produces the secondary colors — cyan, magenta, and yellow. Mixing them all produces white.

How Many Types of Prints Are There in Textiles?

Printing is a process of decorating textile fabrics by application of pigments, dyes, or other related materials in the form of patterns. Although apparently developed from the hand painting of fabrics, such methods are also of great antiquity.

The four main methods of textile printing are block, roller, screen, and heat transfer printing. In each of these methods, the application of the colour, usually as a thickened paste, is followed by fixation, usually by steaming or heating, and then removal of excess colour by washing.

Printing styles are classified as direct, discharge, or resist. In direct printing, coloured pastes are printed directly on the cloth. For discharge printing, the cloth is first dyed with a background colour, which is destroyed by reagents, or reducing agents, carried in a print paste.

Block printing

Wooden blocks, carved with a design standing out in relief, are made from solid pieces of wood or by bonding closely grained woods with cheaper ones. When designs include large areas, these are recessed and the space filled with hard wool felt. Fine lines are usually built up with copper strips, and other effects are obtained with copper strips interleaved with felt.

To facilitate registration of successive prints, or lays, each block has several pitch pins arranged to coincide with well-defined points in the pattern. Cloth is printed on a table covered with several thicknesses of fabric or blanket, the whole covered with a thick sheet of tightly stretched synthetic rubber.

The cloth to be printed is spread on the rubber, either gummed in position or pinned to a backcloth attached to the table. Colour is applied evenly to the block, and the pattern is stamped on the fabric to be printed, using the handle of a small heavy hammer, or maul, to aid penetration of the paste.

More colour is then applied to the block and the process is repeated using the pitch pin to obtain true registration. After the fabric has been entirely printed with one colour, other colours are applied in the same way until the design is complete. Although block printing is becoming too laborious and costly for commercial use, some of the most beautiful prints have been made in this way.

Roller printing

This technique is used whenever long runs of fabric are to be printed with the same design. The modern machine, based on one originally devised in 1783, consists of a large central cast-iron cylinder over which passes a thick endless blanket providing a resilient support for the fabric. Backing fabrics, called back grays, are placed between the blanket and the fabric to prevent undue staining of the blanket.

Although formerly made of cotton fabric, most modern back grays are continuous belts of nylon. The blanket and back gray are appropriately tensioned, so that the fabric moves through the machine as the central cylinder rotates. Engraved printing rollers, one for each colour, press against the fabric and the central cylinder. The pattern on the roller is etched on the surface of a copper shell supported on a mandrel. High-quality engraving is essential for good printing.

Each printing roller is provided with a rotating color-furnishing roller, partially immersed in a trough of printing paste. Finely ground blades (doctor blades) remove excess colour paste from the unengraved areas of these rollers, and each also has a lint blade. The printed fabric passes from the main cylinder and through a drying and steaming chamber to fix the colour.

Although this machine prints only one side of the fabric, the Duplex roller machine, essentially a combination of two roller machines, prints both sides. Modern printing machines are smooth-running precision machines fitted with carefully designed roller bearings and hydraulic or pneumatic mechanisms to ensure uniform pressure and flexibility.

Pressure is regulated from an instrument panel, and each roller is controlled independently. Automatic registration is effected by electromagnetic push-button control, and modern electric motors provide smooth-running, variable-speed drives. The washing of back grays and printer’s blankets has also been automated.

Spray printing is the application of colour from spray guns through stencils and has limited but occasionally profitable use.

Screen printing

Screen printing may be a hand operation or an automatic machine process. The cloth is first laid on a printing table, gummed in position or pinned to a back gray, and then the design is applied through a screen made of silk or nylon gauze stretched over a wooden or metal frame, on which the design for one colour has been reproduced. This is usually a photographic process, although hand painting with a suitably resistant blocking paint is an alternative.

A screen is placed over the fabric on the table against registration stops, ensuring accurate pattern fitting. Print paste is poured on to the screen edge nearest the operator and is spread with a squeegee over the surface of the screen so that colour is pushed through the open parts. The screen is moved until one colour has been applied to the cloth. For application of other colours, the process is repeated with different screens.

With the growing importance of screen printing, the hand operation has been largely replaced by mechanical methods. In some machines, the screens are flat, as in hand printing; others employ rotary screens.

Heat transfer printing

The popularity of polyester fabrics led to the development of a completely new form of printing: heat transfer printing, which prints the pattern on paper with carefully selected dyes. The paper is then applied to the fabric by passing the two together through a type of hot calender, and the pattern is transferred from one to the other. This method opens up new possibilities, such as the production of halftone effects.

In all textile printing, the nature and, particularly, the viscosity of the print paste are important, and the thickeners employed must be compatible with all the other components. For conventional methods the thickeners are such reagents as starch, gum tragacanth, alginates, methyl cellulose ethers, and sodium carboxymethyl cellulose.

Many types of dye can be applied, including direct cotton, vat, mordant, and reactive dyes, as well as pigment colours. Most dyes are fixed by steaming or aging, by a batch or continuous method, and more rapid fixation is effected by flash aging—e.g., allowing a shorter steaming period by employing smaller machines. After steaming, the fabric must be thoroughly washed to remove loose dye and thickener, ensuring fastness to rubbing.

Most textile materials can be printed without special pretreatment, but wool cloths are generally chlorinated before printing. Tops (long, parallel wool fibres), printed in stripes, are used for mixed effects, and printed warps produce shadowy effects. Tufted carpets are printed by a process designed to ensure good penetration.

Which Method of Printing is Most Popular?

There are a variety of printing techniques that designers can use to solve problems and create visual materials. Some are older than others, some are not as easily available as they used to be and others are much more expensive and often out of a clients budget.

Regardless of the specifics or availability, all of these types of printing are still in practice today. It is important to know what you can do with printed materials in order to select the best possible materials and processes for the project.

Offset

Offset printing is still the most commonly used method of printing and is often called offset lithography. Offset printing is created using plates generated for each color used in the printing process. Some projects may call for 2 colors, some may use a standard 4 color CMYK process and others can require even more than that with specialty spot colors, varnishes and a variety of coatings also available.

There are two kinds of offset printing called Sheetfed, in which individual sheets are fed into the printer, and Web, which prints from large rolls and can be used to quickly produce very large quantities of printed materials such as newspapers.

Flexography

Typically operating with web presses, flexography does not use the standard plates of offset lithography. Instead it uses rubber plates and water based inks which dry quicker and allow for faster production times. Faster drying times also allow for more effective results on materials like plastic which does not absorb ink like paper does.

Engraving

Engraving is perhaps the most expensive of all printing techniques as it is also one of the most time-consuming. It is typically used for fancy gala invitations or business cards of high-ranking officials in large corporations. The engraved image is first carved by hand or machine onto a metal plate.

The engraved spaces are filled with ink and the paper pressed on top of it. The result is slightly raised, crisp images and saturated colors that are nearly impossible to reproduce with other techniques.

Thermography

Thermography may look and feel a lot like engraving when the final product is produced, but the details that are present in the engraving process fall short in thermography.

While the details may only be noticed by designers, typographers and people who pay close attention, they are noticeable. However, thermography is much more cost effective. The process involves laying down ink, adding thermography powder, then using heat to raise the image slightly off of the page.

Silkscreen Printing

Silkscreen printing, or screen printing for short offers a wide range of brightly colored inks and is often used for printing t-shirts, posters and other promotional materials. The process involves a design being laid on top of a screen (originally made of silk although a variety of materials are now used) which is coated with photo emulsion and exposed to light. The emulsion that is exposed hardens and the rest can be washed away leaving a stencil of sorts that ink can be pulled through using a squeegee.

Inkjet

The common household printing solution, inkjet is a feasible solution for small print runs and is available to the general public at an affordable cost. The process involves a printer which communicates digitally with a computer of some sort and physically sprays the ink onto the paper. It normally is used with 4 to 8 inks in a CMYK process and can produce richly saturated colors on a variety of materials.

Digital

Digital printing is a process that uses toner, rather than ink, which sits on top of the piece of paper instead of being absorbed by it. While the quality has increased dramatically since its inception, it still can not match the quality of offset lithography, especially in small details, typography and color-matching. The fact that they do not require unique plates means that they can create individual designs that may have varying details quickly and at a lower cost.

What Are The Types of Printing Plates?

There are several types of plates that could be used for the offset printing process, and some of these include:

Diazo Coated

These plates are coated with an organic compound known as diazo. This allows the plate to hold up on short press runs (anything less than 250,000 paper impressions) with ease.

Photopolymer Coated

These plates are coated with another organic compound known as photopolymer. This improves the plate’s ability to withstand abrasions and to resist wear. It is ideal for longer runs (anything up to one million impressions) and is the most popular type in use.

Silver Halide

These plates are coated with a photosensitive material that is similar to that which coats photographic film. This is only suitable for shorter press runs (of up to several thousand impressions) and is ideal for single colour jobs. During processing, the silver coating is removed.

Electrophotographic

These plates are treated in a way that allows the image area to attract a toner-type ink coating (the ink is similar to that used in toner printers). This type is typically used for two-colour jobs and are placed inside of printing duplicators.

Waterless

These plates have a layer of silicone applied to their surface. This layer only adheres to the non-ink receptive parts of the plate, thereby meaning that the water (which is normally used to keep the ink confined to the image layer) is no longer needed.

Is Print CMYK or RGB?

For years, commercial printers have told graphic designers to convert RGB colors to CMYK before packaging your files to send to print. This is to make sure you can accurately see what the colors you are using will look like in print, since your computer monitor displays color in bright RGB while print uses CMYK. This conversion is no longer required in all cases.

No harm will be done if you stick to this old habit, but advances in printing workflows and growth in the use of commercial digital printing have eliminated it as a necessity. Some modern printing workflows even prefer files with RGB colors.

RGB and CMYK are the color processes everyone is familiar with. RGB is an additive process, meaning it adds red, green and blue together in varying amounts to produce other colors. CMYK is a subtractive process.

Different amounts of cyan, magenta, yellow and black are used to “remove” reflected colors from paper to create other colors we can see. The two processes have different ranges of color, with RGB providing a wider array of possibilities.

RGB is used in electronic devices, like computer monitors, while printing uses CMYK. When RGB is converted to CMYK, colors can look muted. Designers were often disappointed when their printed piece looked different than what they had been seeing on screen. To avoid this disappointment, printers told designers to convert colors to CMYK so they’d see them more accurately on their computer.

Now, modern workflows allow printers to use color profiles that automatically match CMYK ink to RGB values to produce results that are much more similar. Additionally, commercial digital printers can use inks beyond just CMYK to closely match the wider color gamut of RGB.

Designers actually gain some added benefits under this new approach. RGB files tend to be smaller; it’s always easier to move and manipulate smaller files. Since most designers today design for print and digital applications at the same time, keeping files in RGB gives you more flexibility as well.

If you’re not sure if you can to let go of this old habit, check with your printer. They’ll tell you whether their workflow still needs you to convert or not.

Which is Best for Printing RGB or CMYK?

RGB is an additive color model, while CMYK is subtractive. RGB uses white as a combination of all primary colors and black as the absence of light. CMYK, on the other hand, uses white as the natural color of the print background and black as a combination of colored inks.

Graphic designers and print providers use the RGB color model for any type of media that transmits light, such as computer screens. RGB is ideal for digital media designs because these mediums emit color as red, green, or blue light.

With the RGB color model, pixels on a digital monitor are – if viewed with a magnifying glass – all one of three colors: red, green, or blue. The white light emitted through the screen blends the three colors on the eye’s retina to create a wide range of other perceived colors.

With RGB, the more color beams the device emits, the closer the color gets to white. Not emitting any beams, however, leads to the color black. This is the opposite of how CYMK works.

CYMK is best for print materials because print mediums use colored inks for messaging. CMYK subtracts colors from natural white light and turns them into pigments or dyes. Printers then put these pigments onto paper in tiny cyan, magenta, yellow, and black dots – spread out or close together to create the desired colors.

With CYMK, the more colored ink placed on a page, the closer the color gets to black. Subtracting cyan, magenta, yellow, and black inks create white – or the original color of the paper or background. RGB color values range from 0 to 255, while CMYK ranges from 0-100%.

How is The CMYK Color Model Usually Used?

CMYK is a color model most often used in printing. Also known as the “four-color process”, it stands for Cyan, Magenta, Yellow, and Key (or black) and is a subtractive color model, as opposed to an additive color model like RGB.

In printing, CMYK reduces the brightness, or reflected light, from a white background. It subtracts the amount of white showing through by working in levels of cyan, magenta, yellow, and key to achieve the desired color.

Should I Convert RGB to CMYK For Printing?

RGB colors may look good on screen but they will need converting to CMYK for printing. This applies to any colors used in the artwork and to the imported images and files.

If you are supplying artwork as a high resolution, press-ready PDF then this conversion can be done when creating the PDF. If you are supplying artwork in its original formats, such as InDesign or QuarkXPress, then it is better to convert colors to CMYK before supplying artwork and files. This will not only give you a better idea of how the colors will look when they are printed but will avoid any problems with color shifts that may occur.

What is The Difference Between Web and Print?

Both print and web are powerful mediums that have the power to persuade. If you want to create a website soon, and are thinking about how different web is from the print world, you’ve come to the right place.

User experience

In print, navigation consists of page-turning, a simple user interface. In print medium, the design is entirely made in canvas, with the user walking through information from page to page.

In web design, users scroll through scores of information, and have the ability to jump to content which appeals to them first, rather than going through a linear way.

Also, print design offers one-way communication with the user, while the web has ability to allow two-way communication with readers.

In print, the user is able to physically view and feel the printed material, interacting with it directly. In web, the user views the content through a screen.

To engage user’s senses and interest, print design may include experiences such as adding texture, shape, or printing effects like letterpress, embossing, varnishing, lamination and so on.

Web design, on the other hand may include interactive elements such as animation, mouse-over effects, hyperlinking, instant messaging and so on, along with audio and video.

For example, a printed brochure might have a nice printing effect such as embossing, and its content might be neatly packed into blocks with attractive images picking user’s interest. The brochure might have a certain feel to its paper, with users appreciating the rustle and the smell of the paper.

A web brochure on the other hand, might have animated illustrations that might be helpful to users, along with hyperlinks that link readers with additional information about its content.

Both print and web design have their own separate appeal and advantages.

Size

In print, the reader is able to physically view the print material, and so the designer must take into account the size, weight, and materials, before going into the creative stage.

The content produced during the creative stage will be included into the canvas according to the measurements that were pre-set.

As print has a fixed size, you can work on the canvas provided to you with pre-given measurements, working around the edges.

The design for web is fluid, as the edges and measurements for the web screens change according to browsers, and mobile platforms. The same website for instance would look different on a desktop than its mobile version, with the content aligned differently.

The designer may establish the font size, colors, background image, spacing etc., which is then applied to the content produced.

The alignment of content in a website layout would change, as content is updated and added by the designer. In this way, websites keep changing according to the expansion and reduction of content on a daily basis.

Due to the inflexibility with printing, one can determine with absolute certainty how the user is going to view and interact with the printed design.

However, due to the variations in screen sizes and resolutions on the web, the end result cannot be predicted accurately.

The designer will have to add in the flexibility of adjusting to different screen sizes in order to produce the best results for all users. In this way, web and print design differ acording to size.

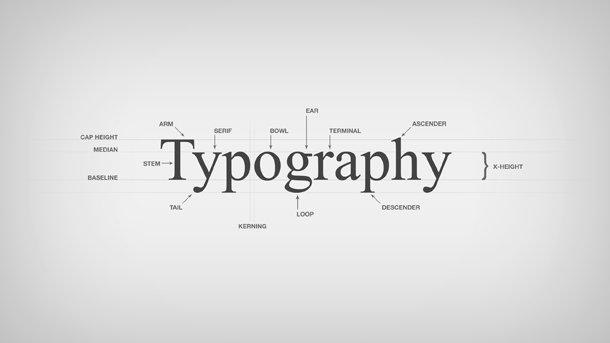

Typography

The types of fonts available to pint designer sare almost unlimited, as there’s an array of fonts available on print designing tools such as InDesign and Corel Draw.

The fonts can be used as is, as the designer knows the final outcome of the design. In web, however, web fonts are required to be used, ones that are simpler than print fonts and which have increased legibility.

Readers will be undergoing fatigue while viewing websites on screens, and so, the fonts must be easier to understand at first glance. The text has to be accurately spaced for viewing on screens, so that not much strain is put on the eyes of the reader.

Even now that you are reading this blog post, you can see how the text is divided into short paragraphs of few lines, with optimum spacing between each paragraph and image.

On the web, the reader has scores of data to digest and various distractions to go through.

There are also various web fonts directories available, such as Google Fonts and Adobe Edge Web Fonts, that make web fonts easily available to web designers.

For both web and print design, factors such as kerning, tracking, leading and ascender and descender heights must be taken into account.

Kerning provides adjustment to spacing between pairs of alphabets, while tracking or letter-spacing provides adjustment to spacing of a word or block of text.

Color

In print design, designers use CMYK, the ink colors Cyan, Magenta, Yellow and Black. Individual colors are formed from mixing percentages of the above four colors, in print.

Colors then have codes, that signify the base colors that produce the given color. This is based on subtractive addition of color, by combining all colors you get black.

Screen and lighting technology is based on RGB, which is the colors Red Green and Blue.

The various colours are encoded as a value of 0-255 for each of the three colours, and works in an additive manner. When all the 3 values are maxed out at 255, the color displayed will be white.

Due to the differences in how the color is handled between screen and print, there is a need for calibration between the screen and printer to produce the most accurate print.

While on screen, a picture might appear dull or bland, this might be because the screen itself is off on the color calibration.

The color displayed on screen might not be the same color present when the picture is printed due to the mismatch in calibration.

For professional photo and video editing, a screen with accurate calibration is therefore required. Apple’s screens for their Mac lineup is particularly known for their high color accuracy.

Resolution

In the actual printing process, DPI (dots per inch) comes into play, and equipment that prints at a higher DPI will produce a higher resolution image.

PPI (pixels per inch) refer to the number of pixels present per inch of screen space, and on web, the general acceptable PPI value for images is approximately 72 PPI.

PPI is responsible for the quality of the image, and by extension, the size it can be scaled to. DPI has no relevance for web design, as it signifies how ink is printed, and is also not responsible for the size of an image.

PPI on the other hand, has an inverse relationship with the print size. Higher the size of the print, less is the PPI and vice versa.

What is a Web-to-Print Portal?

The generalized answer to describe this technology is the use of digital web services in the production of commercial printing. For customers this will take the form of an online web ordering portal, where you can choose, design, and order your printed items. This information will then flow into the printer’s workflow and provides them with print-ready files going into production.

There are many ways that having a web2print solutions option can benefit your company and make ordering easier and more efficient. The web-to-print system helps by,

- Promoting Brand Consistency – When using web2print solutions, you will be able to have templates set to make sure that all of your printed items remain brand consistent. The templates can be made to fit your design and certain information can remain static so there is consistency from item to item.

- Integrating Purchasing, Shipping, and Billing – With this web2print solutions technology, you will be able to purchase your items, designate your shipping requirements, and receive your invoice all at one time. This can save administrative costs and also prevent purchasing errors.

- Allowing Approval of Proofs without Face to Face Meeting – With web2print solutions, your proofs are one click away. You will no longer have to travel to the printing company or rely on shipping to receive your proofs and send back your approval. You will be able to see your proof immediately onscreen and approve it right away where it will then be sent into production. This proofing method can save days as well as a lot of unnecessary travel.

- Being Able to View a Catalog of Products at a Glance – A great benefit of the web2print solutions system is that you will be able to view a catalog of all the items that you print at a glance. This can save a great deal of time for purchasers and other administrators who normally have to look up previous orders and information from last job runs.

- Providing Ordering Capabilities From Anywhere – With web to print services, you will be able to log in and order from anywhere you have a computer. If you have multiple people purchasing they will be able to order remotely and there are administrator approval functions as well to control outside purchasing.

- Reduction of Overall Administrative and Inventory Costs – With order on demand ability and shorter lead times, due to the reduction of prepress times, you will be able to maintain less of an inventory. You will also see a reduction in overall administrative costs as you will eliminate the multiple steps that normally go into a print order process. You will also have greater controls over ordering as you will be able to designate who can order and approve or view their transactions at any time.

How do I Enable Web Printing?

Each printer that will be available with Web Print must have Web Print enabled. Smaller organizations might want to make all printers available, while larger organizations might want to restrict to a subset e.g. limiting access to printers located in public areas.

To enable Web Print for all printers:

- Click the Printers tab. The Printer List page is displayed.

- Select the The template printer.

- Select the Enable Web Print (users may upload documents to print) check box.

- Copy the setting to all other printers using Copy printer settings.

If your Web Print server is for Email to Print only, you should see the full set of supported document types in the Email to Print set up area. If there is a problem, temporarily enable Web Print so you can take advantage of the additional status information provided in the Web Print setup.

How do I Print a Web Page on Google Chrome?

The free Webpage Screenshot extension for the Chrome browser lets you save an entire Web page as a PNG file. For $20, the FastStone Capture program saves all or part of your screen as JPEG, TIFF, BMP, PDF, and other file formats, and also captures your onscreen actions as a video file.

The simplest of those methods is to press the Print Screen key (or Alt+Print Screen) in Windows, or either Command+Shift+3 or Command+Shift+4 on a Mac. Another is to use the Chrome browser’s Print > PDF > Save as PDF option.

Webpage Screenshot adds a camera icon to the top-right corner of the Chrome window (to the right of the address bar). The first time you open the extension, you’re warned that the program is requesting access to “your data on all Web sites” and “your tabs and browsing activity.”

The vendor’s FAQ page explains that the warning is due to the program’s use of Chrome’s CaptureVisibleTab command. The developer claims it collects only anonymous usage statistics, a feature that can be disabled without affecting the program’s operation.

To do so, click the extension’s icon, choose “settings” under “Suggest a new feature,” open the Advanced options at the bottom of the screen, and uncheck “Enable anonymous usage statistics.”

When you’re ready to capture a page, click the camera icon and choose either “Visible screenshot” or “All page screenshot.” A new tab opens with the captured page and editing options in a window at the top of the screen. Also displayed are buttons for printing or sharing the page via email, social networks, and other services.

When you click the Save button on the far right, the page is downloaded as a PNG file. You can change the default image format to JPEG in the extension’s settings, which also shows options for custom keyboard shortcuts and setting delays for your page grabs from one to 10 seconds.

What Does Online Print Mean?

Printers work offline when they have a hard-line connection to the computer holding the document. The printer requires a means of communicating with the computer so it can read and transmit from the hard-drive to the print function.

The printer itself does not have a hard-drive and cannot perform without a means of viewing your document. Bringing a printer online means it can print documents without a direct connection to the computer. The document is transmitted through the remote connection while the printer reads and prints.

In order to have a printer online, it requires a network connection. In some cases, a hard line ethernet connection to the internet is used but many printers also offer WI-FI as a network connection option. Setting up the printer is simple for a single computer, but an encrypted and secure network requires more work to bring the printer online.

Connecting to the WI-FI Network

You send a document to print but nothing happens. So how do you find your printer queue and push the print command through? First, you need to connect the printer to the same WI-FI network as your computer. Otherwise, the print task you created doesn’t have a printer or it will send to a different printer than intended on the network.

Read Also: How can Your Customers Benefit from Web-to-Print Technology?

The printer itself has a simple menu where you can access the available WI-FI networks. Make sure you connect to the correct network. Go back to your computer and you should see the printer as available. Click Print on the document, select the printer and push through the task. This will send it to the printer queue and execute the task.

Connecting Through Ethernet

An ethernet connection is similar to WI-FI in that you are simply bringing the printer online and connecting it to a network. To do this, you simply plug the hard-line cord into your internet port and voila, it’s online.

If you are operating in a basic network without a firewall, press Print on the document and select the printer. If you have a firewall and the printer is not approved on your network, you must install it on the network by following the prompts and entering the network key or password.

Is Your Printer Installed?

If you bring a printer online and it does not work, you may need to install the printer driver on your computer for it to communicate and work. Say, for example, your printer that’s offline is a Dell, and no matter how many times you reconnect it, the printer inevitably goes back offline.

You may be able to permanently solve this by making sure the printer is properly configured. Access your settings, then click Devices. Select Printers and Scanners and choose Add Device. You can install the printer to your computer to ensure it works properly at this point.